專業打造 信賴合作

Coolmosa專注於提供高品質的壓鑄製造服務,在臺灣與中國設有生產工廠。我們擁有從模具開發、鋁合金與鋅合金壓鑄生產到表面處理的完整垂直整合能力,確保產品從開發到量產的每個環節均符合嚴格的品質標準。

我們的產品廣泛應用於醫療設備、汽車零組件、精密工業產品、小型發動機、電子與顯示器組件、工業控制設備、網絡通信設備及專業照明應用,能夠滿足不同產業對於高精度、優異機械性能及嚴苛環境耐受性的需求。

壓鑄

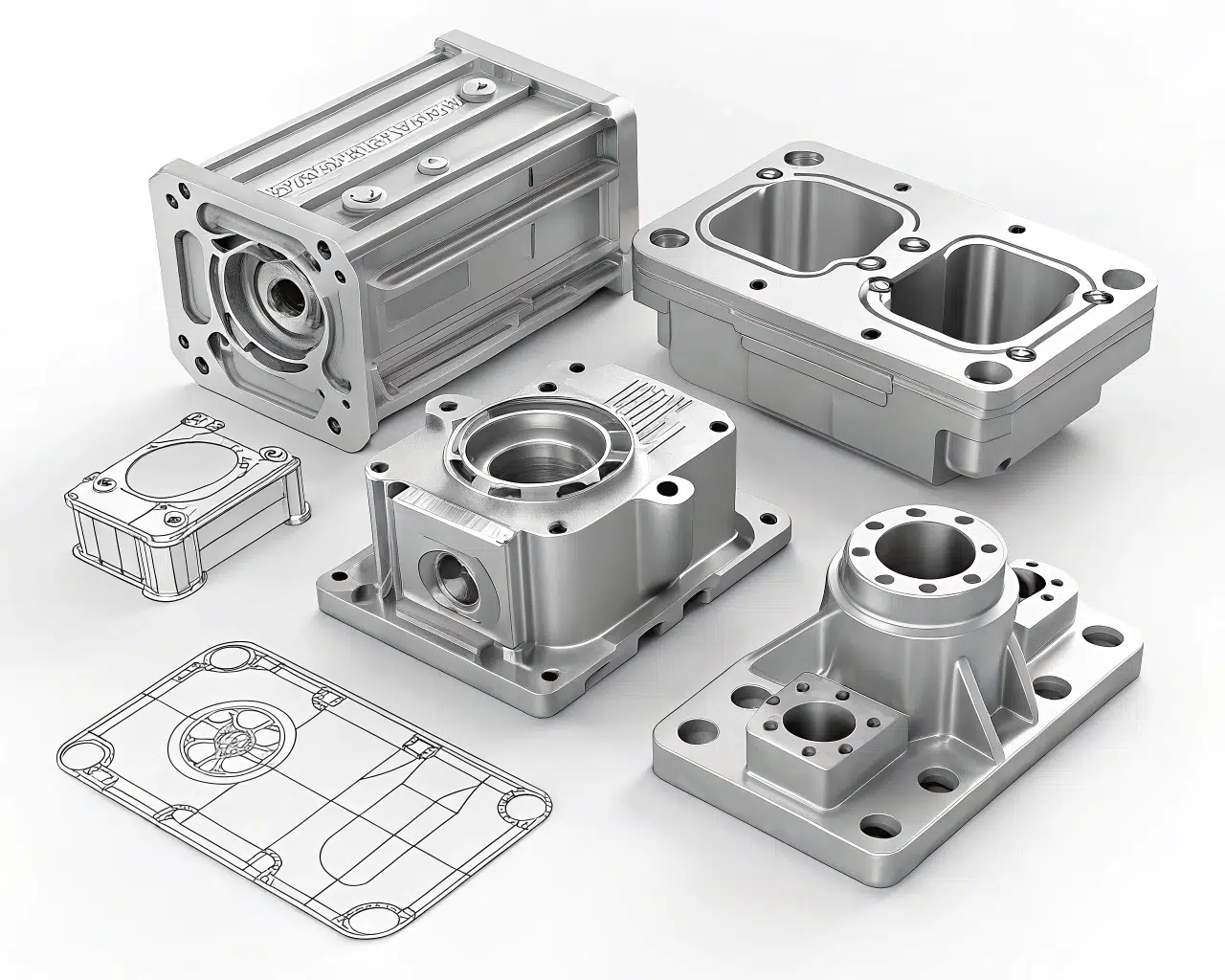

從原型到量產—高效金屬壓鑄

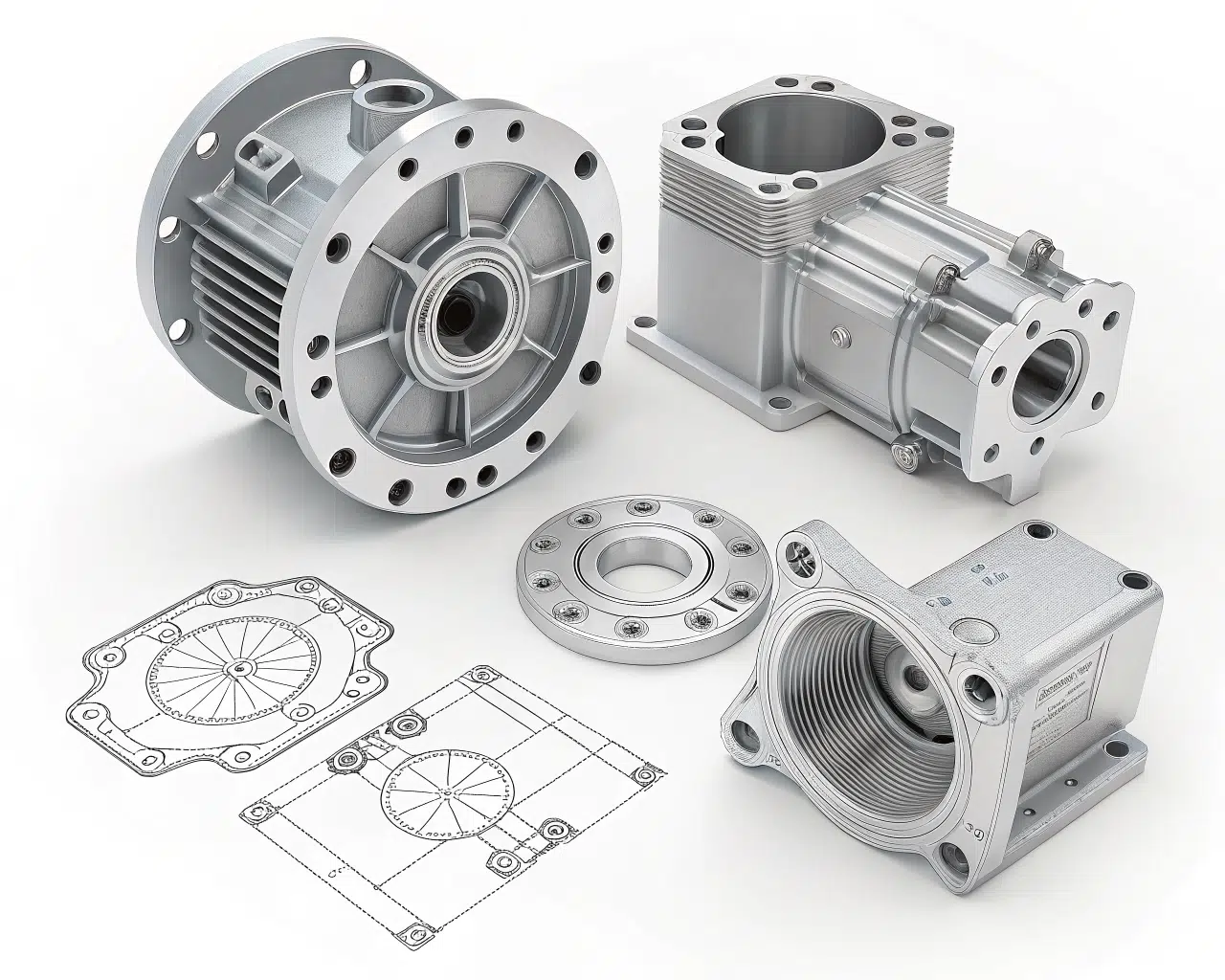

壓鑄(Die Casting)是一種高效、精密的金屬成型工藝,主要用於生產複雜形狀、高精度、高強度的金屬零部件。相較於傳統機械加工或砂模鑄造,壓鑄可在幾秒鐘內完成一個零件,適合中、大批量生產,大幅降低生產成本。

Coolmosa配備先進的壓鑄生產設備,包括150噸至800噸的冷室壓鑄機(適用於鋁合金壓鑄)以及30噸至125噸的熱室壓鑄機(適用於鋅合金壓鑄),能夠生產高精度、複雜幾何形狀的零件,滿足客戶對品質與效率的雙重要求。

精密技術 無縫整合

我們擁有專業的壓鑄模具開發與製造團隊,能夠根據客戶的需求,提供精確的生產計劃與最佳解決方案,確保零件品質與精密度。

從設計、模流分析、試模驗證到正式生產,我們嚴格控管每一個環節,確保模具符合高效能與耐用性的標準。

此外,Coolmosa也提供二次加工服務,包括CNC加工、攻牙、各式表面處理及組裝,確保產品在出貨前即達到客戶的最終規格需求,實現一站式服務的便利性。

承諾卓越 專注品質

Coolmosa致力於為客戶提供高品質的產品與專業服務,並將嚴格的品質控制(QC)貫徹至每個生產環節。從製造加工到包裝出貨,我們全面監控每一道流程,確保產品符合預期標準,為客戶提供值得信賴的解決方案。