三十年卓越 一站式解決方案

Coolmosa深耕鋁擠型產品領域超過30年,憑藉卓越的技術與完整的垂直整合製造能力,為眾多客戶提供高效能、高性價比的解決方案。

我們以豐富的經驗與技術優勢為基礎,持續推動創新,確保產品滿足市場需求,並協助客戶提升競爭力。

我們的垂直整合製造模式使生產流程更加高效、靈活、穩定,無論是大批量生產或小批量客製訂單,我們都能提供最優化的解決方案,幫助客戶提升市場競爭力,加速產品上市時程。

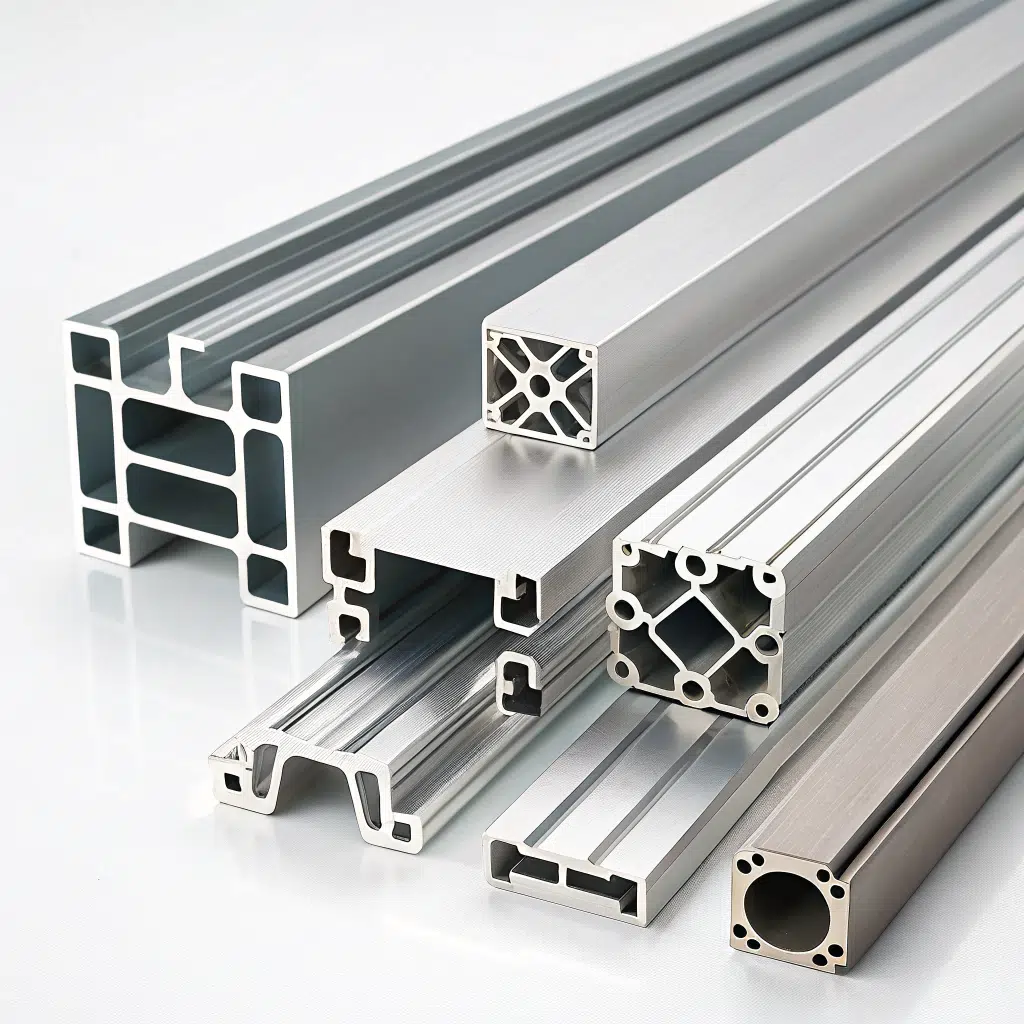

鋁擠型技術

高效散熱.結構可靠

鋁擠型是一種高強度、輕量化、耐用且導熱性能優異的產品。透過高溫加熱鋁錠並利用擠壓與模具成型,可打造形狀複雜、結構精密的產品。

此技術廣泛應用於電子設備、工業電腦機箱、散熱器、汽車零件、建築結構等領域,尤其適用於需要高效散熱、結構輕盈的設計需求。例如,現今許多工業電腦與微型電腦機箱,為了提升散熱效果與降低成本,已廣泛採用鋁擠型材結構,進一步優化產品性能。

精密製造 完美落實

Coolmosa提供一站式鋁擠型製造解決方案,從模具開發、鋁擠型材機箱生產到最終組裝,確保產品符合精密規格與高品質要求。我們擁有先進的生產技術與完整的品管流程(QC),確保每個零件在強度、耐用性、導熱性能等方面達到最高標準。

此外,我們提供全面的後續加工服務,提供CNC精密加工、攻牙、沖壓、表面處理,並支援次組立、全組立及最終測試,確保產品在交付前即符合客戶的最終需求。

優化製造 創造最大價值

我們以精密分析、模具開發、快速生產、品質保證為核心競爭力,透過完整的生產流程控管,確保客戶獲得高效、可靠的產品。我們自豪於我們的製造能力與交貨速度,確保每個專案都能準時完成,並提供超越客戶期待的產品與服務。

選擇Coolmosa,您將獲得專業的技術支援、高品質的產品與高效的服務,助力您的產品在市場中脫穎而出。